Cleanroom testing

Air Changes per Hour

Air Changes per Hour

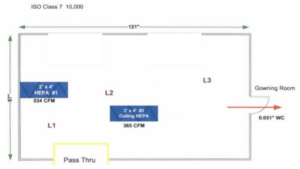

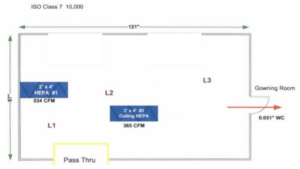

Air changes = CFM (60) / Cu ft

Room: 10’ x 8’ x 8’ ceilings = 640 cu ft

Airflow: 534 CFM + 365 CFM = 899 CFM

899(60) = 53,940/640 cu ft = 84 air changes per hr

Cleanroom certification

Our performance team will certify the rooms to industry standards including, but not limited to:

National Environmental Balancing Bureau (NEBB) – Procedural Standards Certified Testing Cleanrooms

certification numbers:

Additional cleanroom testing includes, but is not limited to:

Temperature and Humidity

Temperature and humidity reading taken through out the cleanroom. We normally take them in the same locations as the Particle counts. Data trending is available.

Noise Level

Sound Level measurements taken through out the cleanroom. We normally take them in the same locations as the Particle counts.

Light Level

Light Level measurements taken through out the cleanroom. We normally take them in the same locations as the Particle counts.

Particle counts (non-viable)

Optional Testing

Air pattern testing – dependent on ISO class. Variable particle testing.

Room Pressure Measurement and Adjustment

Calibration or verification of cleanroom gauges.

Cleanroom testing

We are able to perform the functional test that is best for you and your customer.

In some cases, you may want all three tests completed.

As Built

All HVAC components operating as designed, room empty no furniture or equipment. This test is used to prove the room was built and works as specified.

At Rest

All HVAC components operating as designed, all furniture and equipment moved into the room, equipment not running. This test used to prove the with equipment in place and furniture in place that the room still works as designed.

Operational

This to prove room working with personnel and equipment in normal operational mode. If only one test is picked from this list, this one would be the most important.

Cleanroom testing

HEPA filter balance:

HEPA/ULPA leak testing:

Cleanroom testing

Make up Air Performance Testing

Air Handler Performance Testing

Air Handler Static Profiling

Exhaust Fan Performance Testing

Supply and Exhaust Diffuser Balancing

Cleanroom testing

Air changes = CFM (60) / Cu ft

Room: 10’ x 8’ x 8’ ceilings = 640 cu ft

Airflow: 534 CFM + 365 CFM = 899 CFM

899(60) = 53,940/640 cu ft = 84 air changes per hr

Cleanroom consulting

Are you having problems with your controlled cleanroom environment and don’t know where to start?

Our expert team can assist with troubleshooting.

From gowning procedures to cascading room pressurizations, we have the knowledge, training, and expertise to identify opportunities to improve the performance of your cleanroom environment.

Terms and conditions

©2025 Clean Rooms International, Inc