Cleanroom Systems & Components

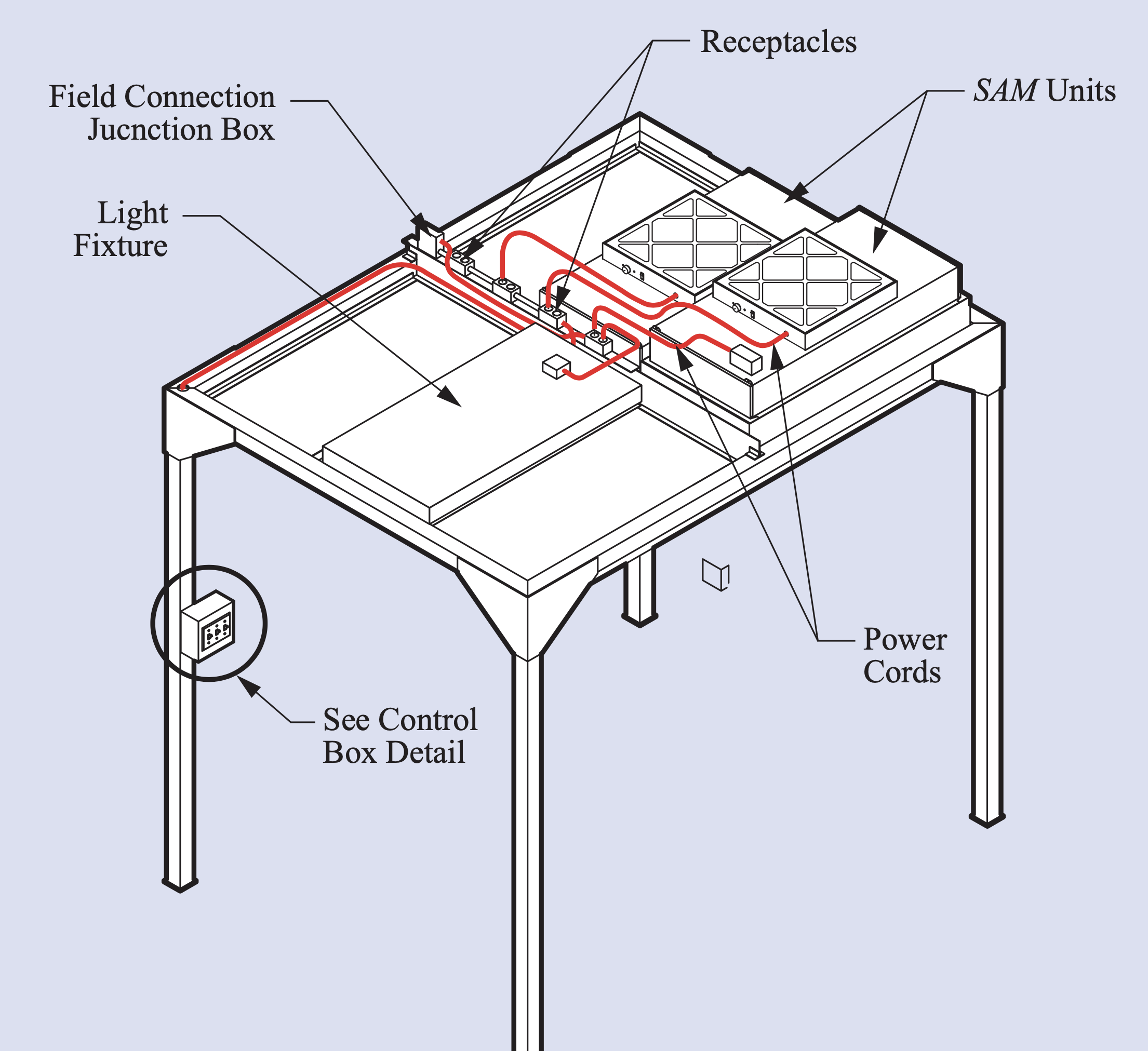

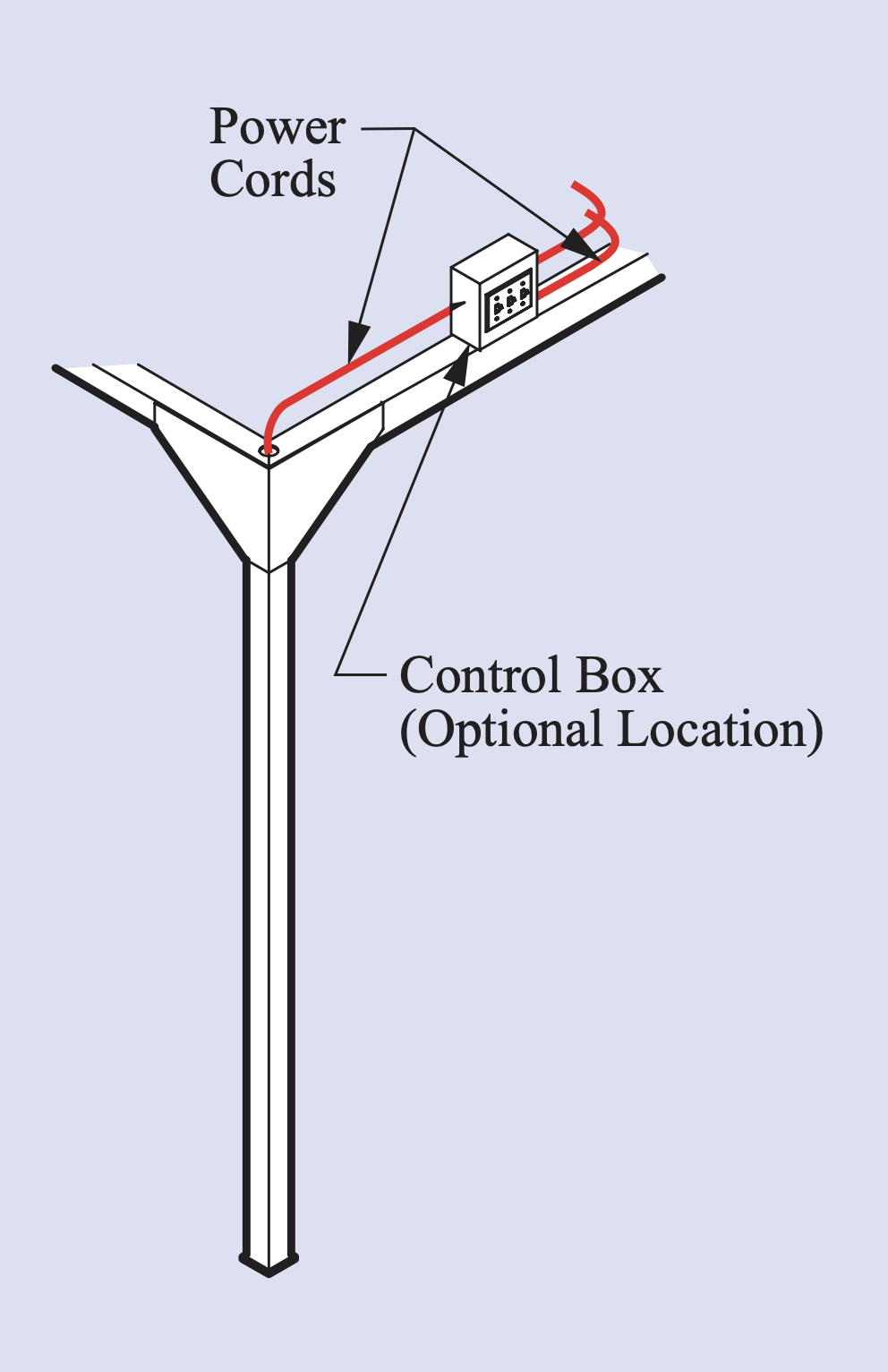

SAM® Fan Filter Units and Light Fixtures are equipped with power cords for plugging into receptacles mounted on a top cross rail.

Receptacle(s) are connected to a flexible conduit that connects to a field connection junction box.

A qualified electrician can then connect the host building power to the QS Softwall Cleanroom.

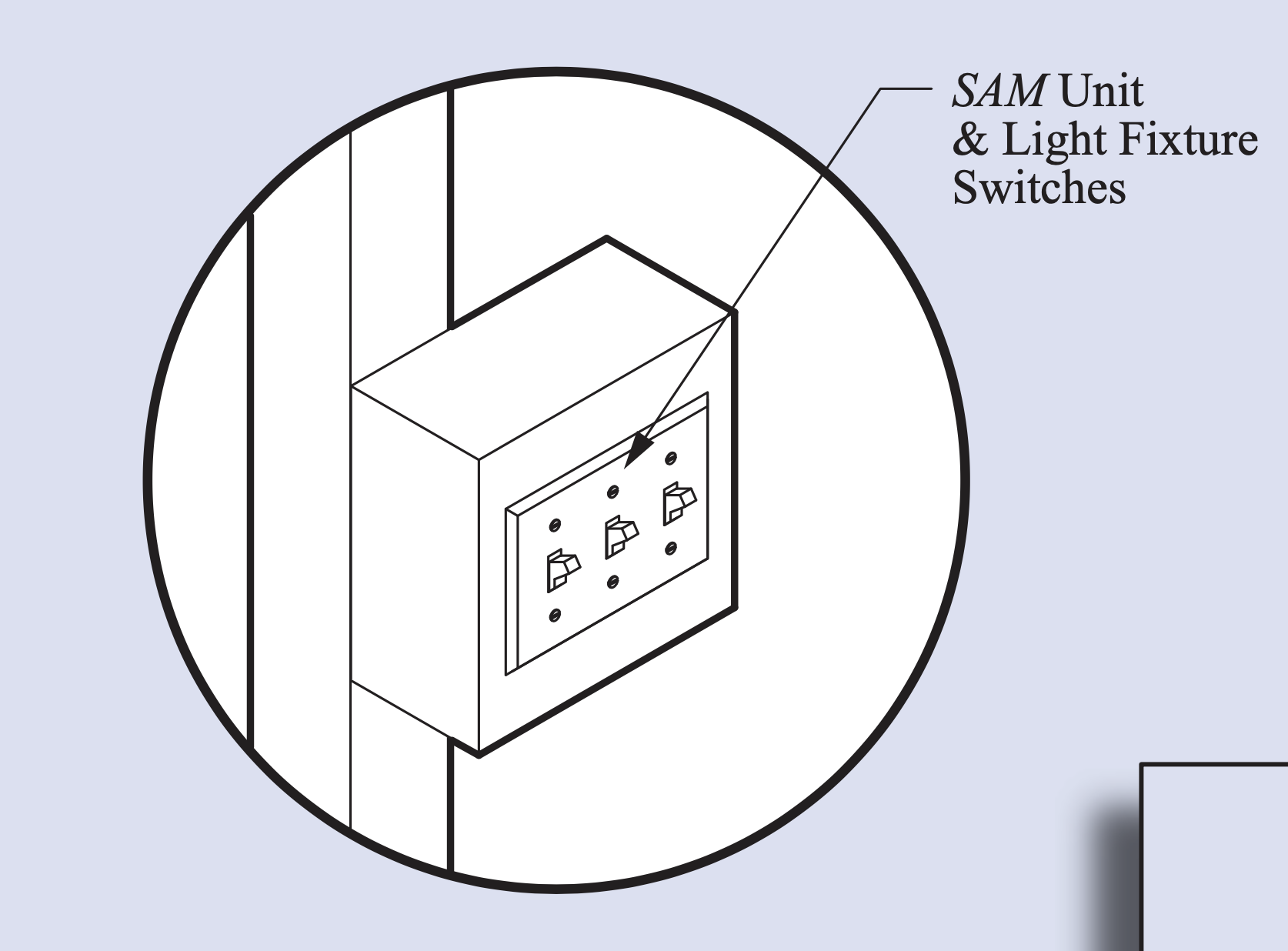

A control box mounted on a leg is equipped with switches for the SAM Units and Light Fixtures. The number of switches will be appropriate or in direct proportion to the number of SAM units and light fixtures.

Connecting to the building power source and compliance with state, city, county, or township codes are the responsibility of the buyer.

Flexible Solutions Softwall Cleanrooms are considered a piece of equipment and are in compliance with accepted national practices for wiring of equipment.

Lead time for the electrical option requires an additional 5 business days. Consult with the factory for more information.

General Information

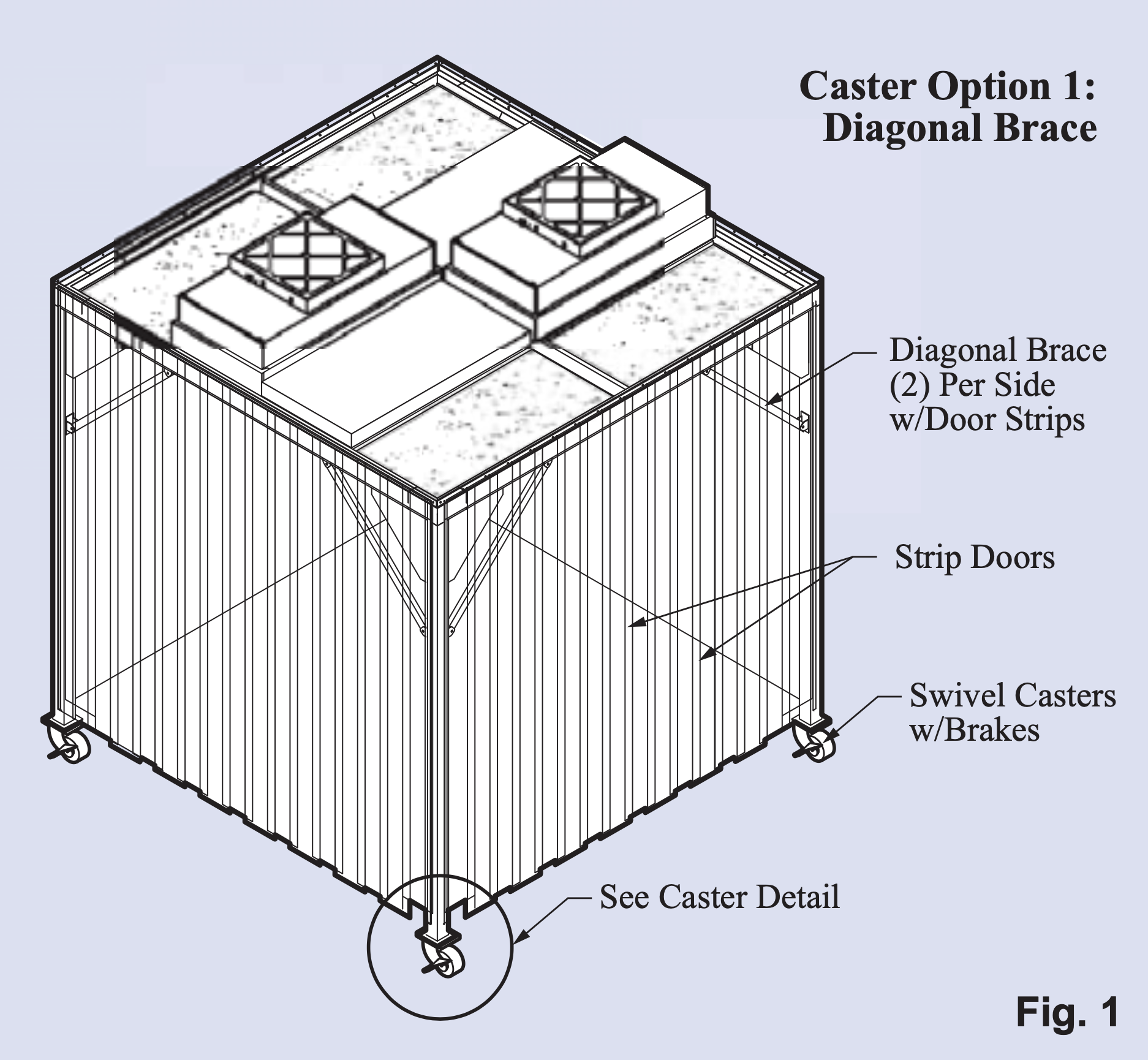

Adding a Caster Package permits the Softwall Cleanroom to be moved from one location to another.

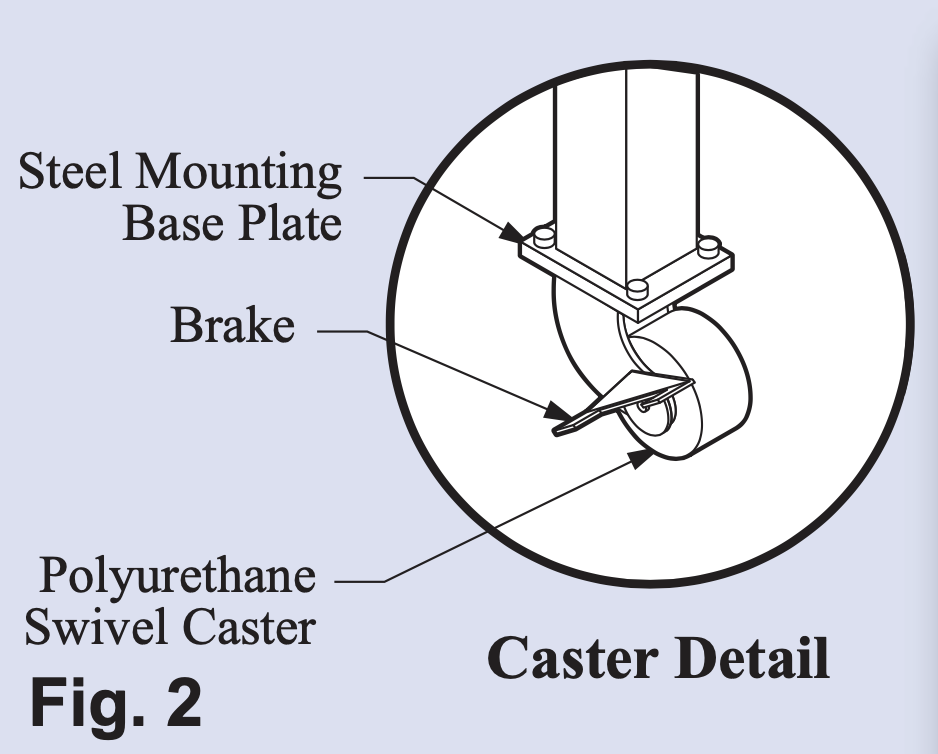

All casters are polyurethane swivel type and are equipped with brakes (Fig. 2) to prevent movement when the cleanroom is in use.

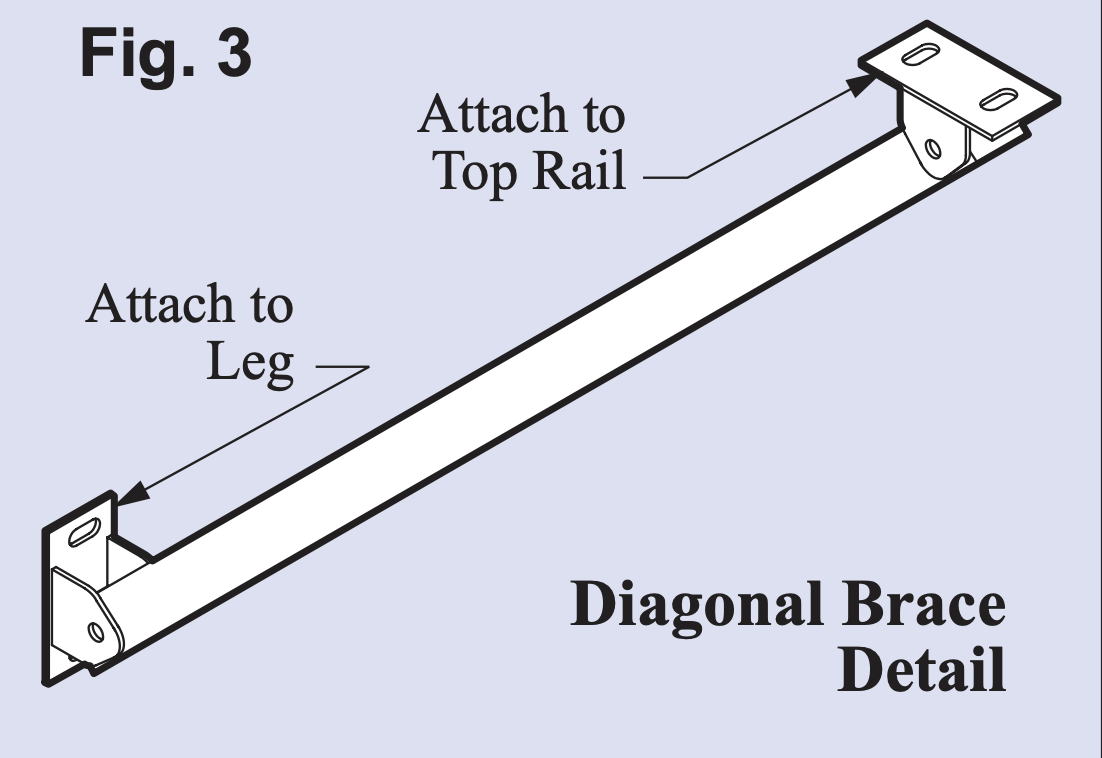

To insure stability during a move, Caster Option 1 includes up to (8) Diagonal braces (Fig. 3). Cleanrooms with 1-4 sides consisting of all strips utilize two (2) Diagonal braces per side as shown on Fig. 1. Diagonal braces can also be used on sides with solid curtains.

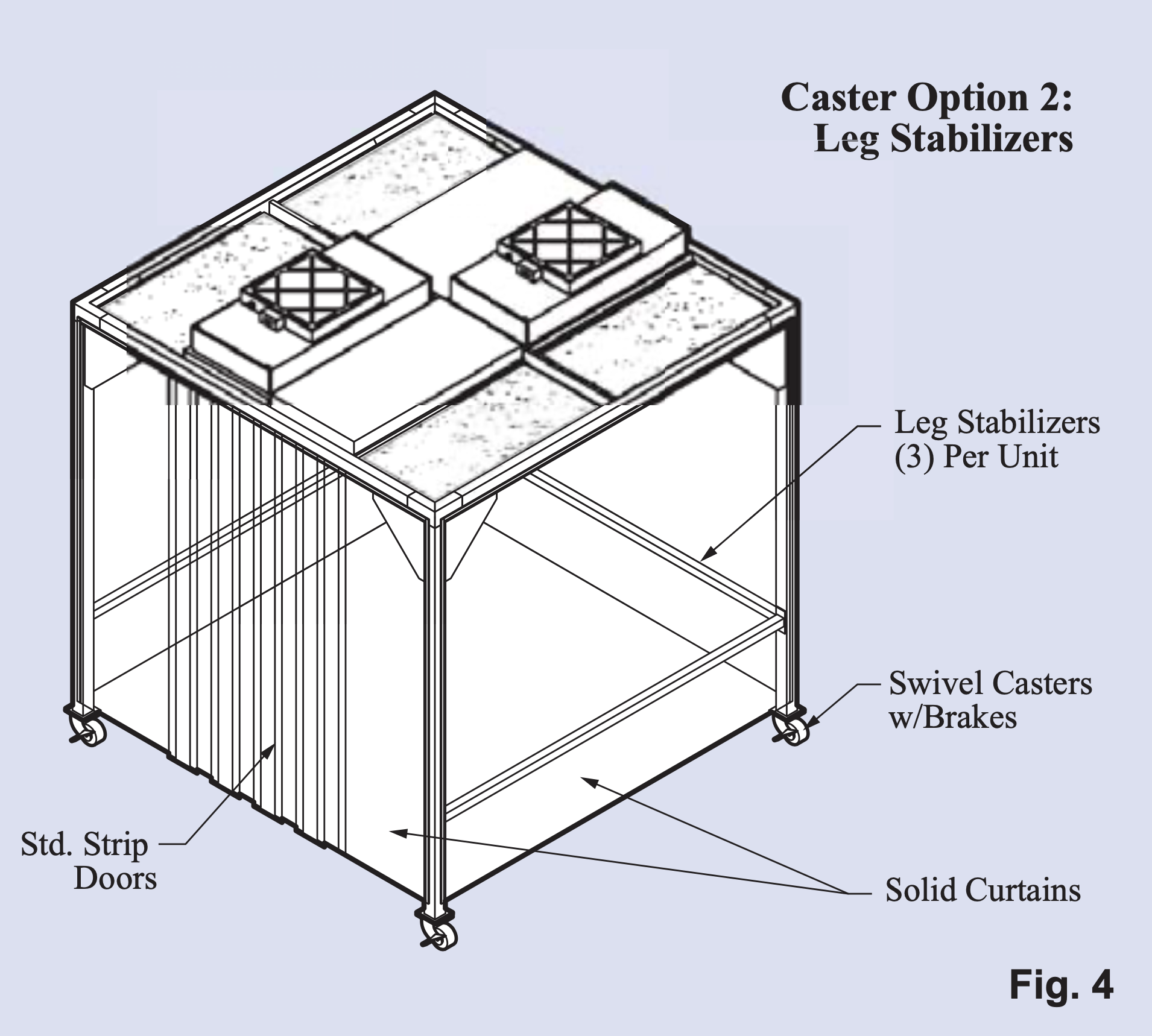

Caster Option 2 includes three (3) Leg Stabilizers for sides with solid curtains as shown in Fig. 4.

Lead Time

Lead time for the electrical option requires an additional 5 business days. Consult with the factory for more information.

Control Box Detail

Available for Built to Order and QS Series

Caster Detail

Diagonal Brace Detail

Leg Stabilizers

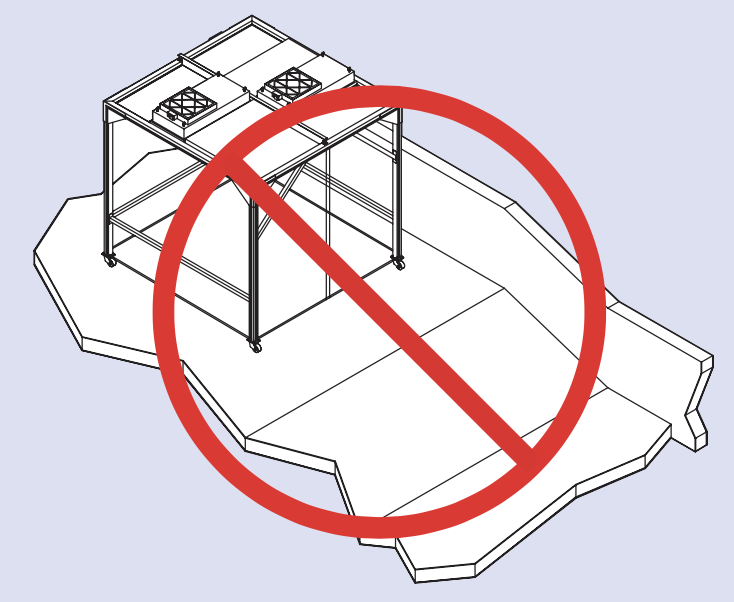

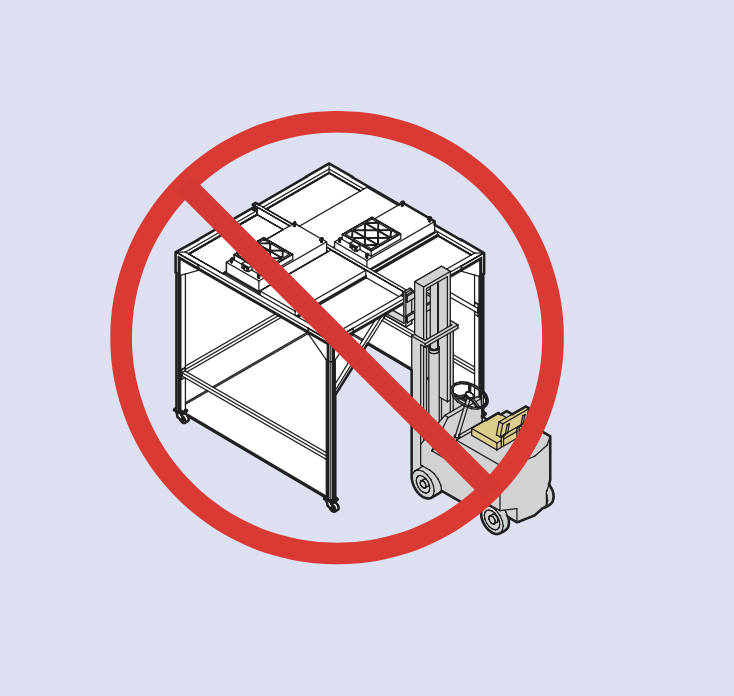

DO NOT attempt to move cleanroom across uneven or inclined surfaces.

When moving a portable cleanroom, DO NOT use a fork lift, portable hoist, pallet jack or other lifting devices.

Mfg. code

Model or Description

805079

Casters, 4” x 2” w/brake (4) req’d.

966002

Diagonal Brace

966018

8 Ft. Leg Stabilizer

966019

10 Ft. Leg Stabilizer

966020

12 Ft. Leg Stabilizer

Curtain Panels

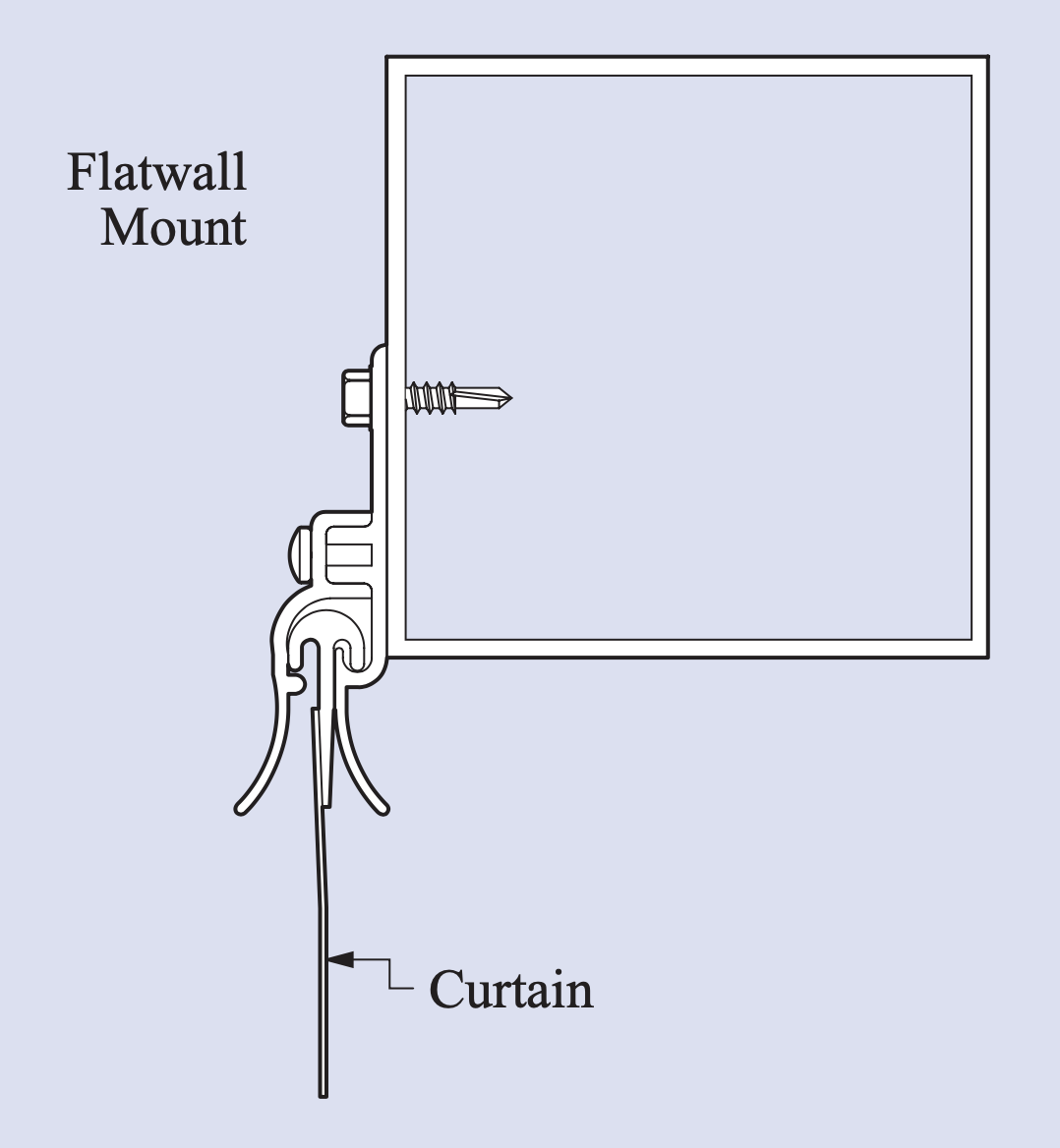

Softwall Cleanrooms designed with standard 40 mil curtain panels are supplied with an anodized aluminum mounting track. (Fig. 1)

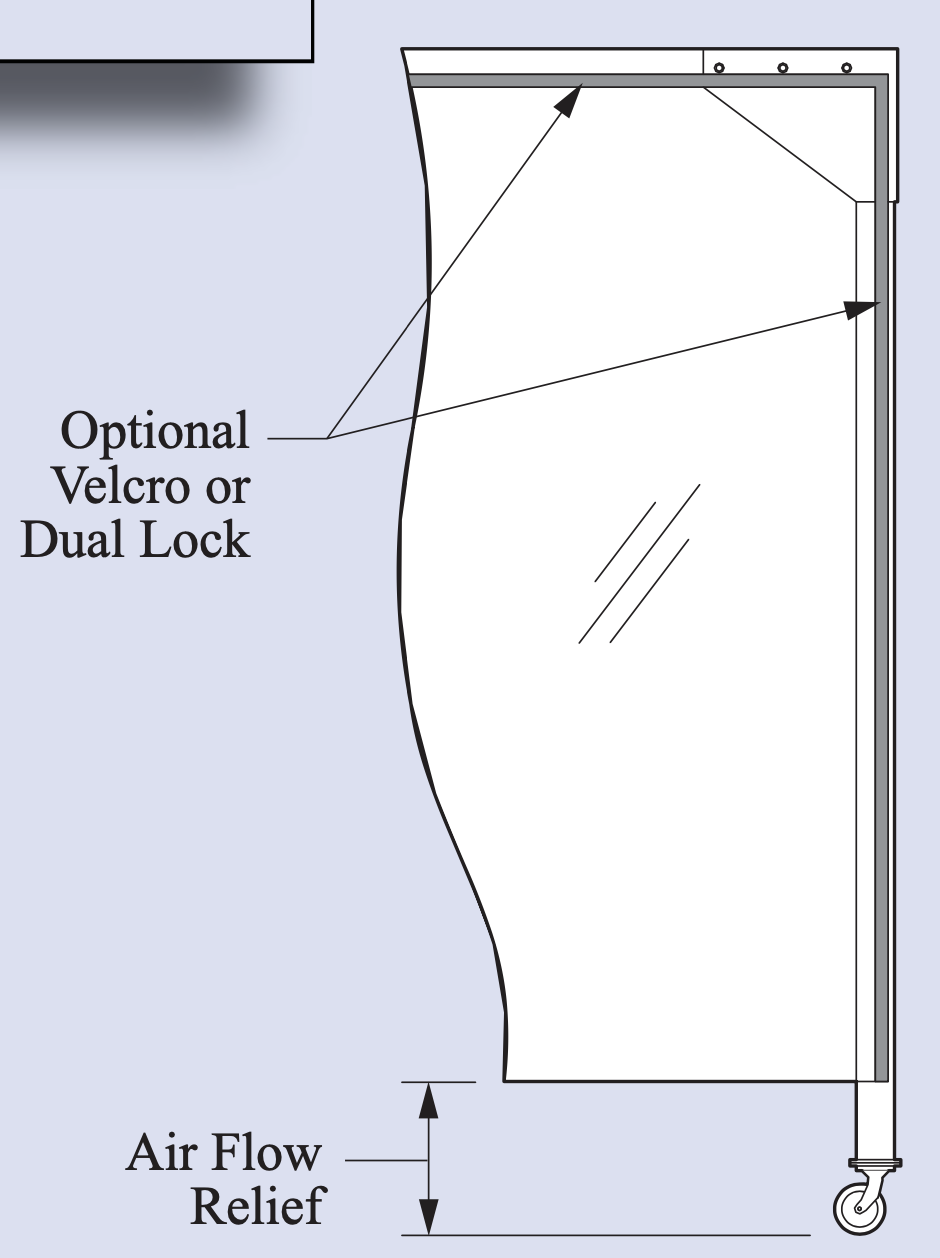

Our engineers factor in the desired velocity and choose the appropriate curtain length for each cleanroom, resulting in proper airflow relief.

Curtain Panel Options

Clear vinyl and antistatic curtain panels are also available in 20, 40, 60 and 80 mil thicknesses. Frosted curtains and various colors including Yellow/Amber, Smoke and Black Opaque are available, as well

Mounting Options

Curtains may be be ordered with Dual Lock or Velcro attached to the tops and sides for attaching to the frame. After the mated piece is attached to the frame on site, the curtain panel is then attached to the frame. Both options ensure a tight seal around the edges at a reasonable cost. Consult with our factory for the proper curtain attachment for your application. (Fig. 2)

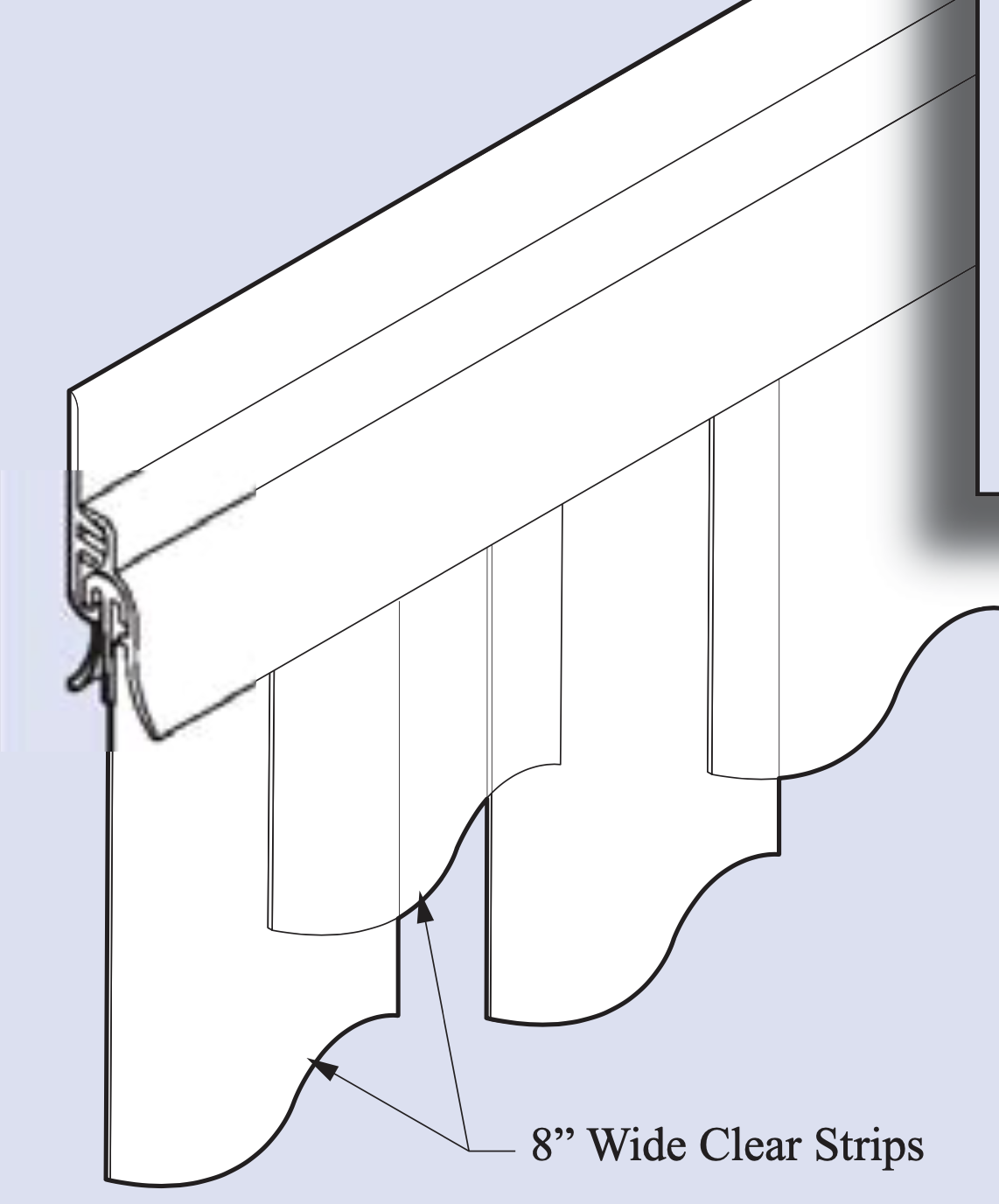

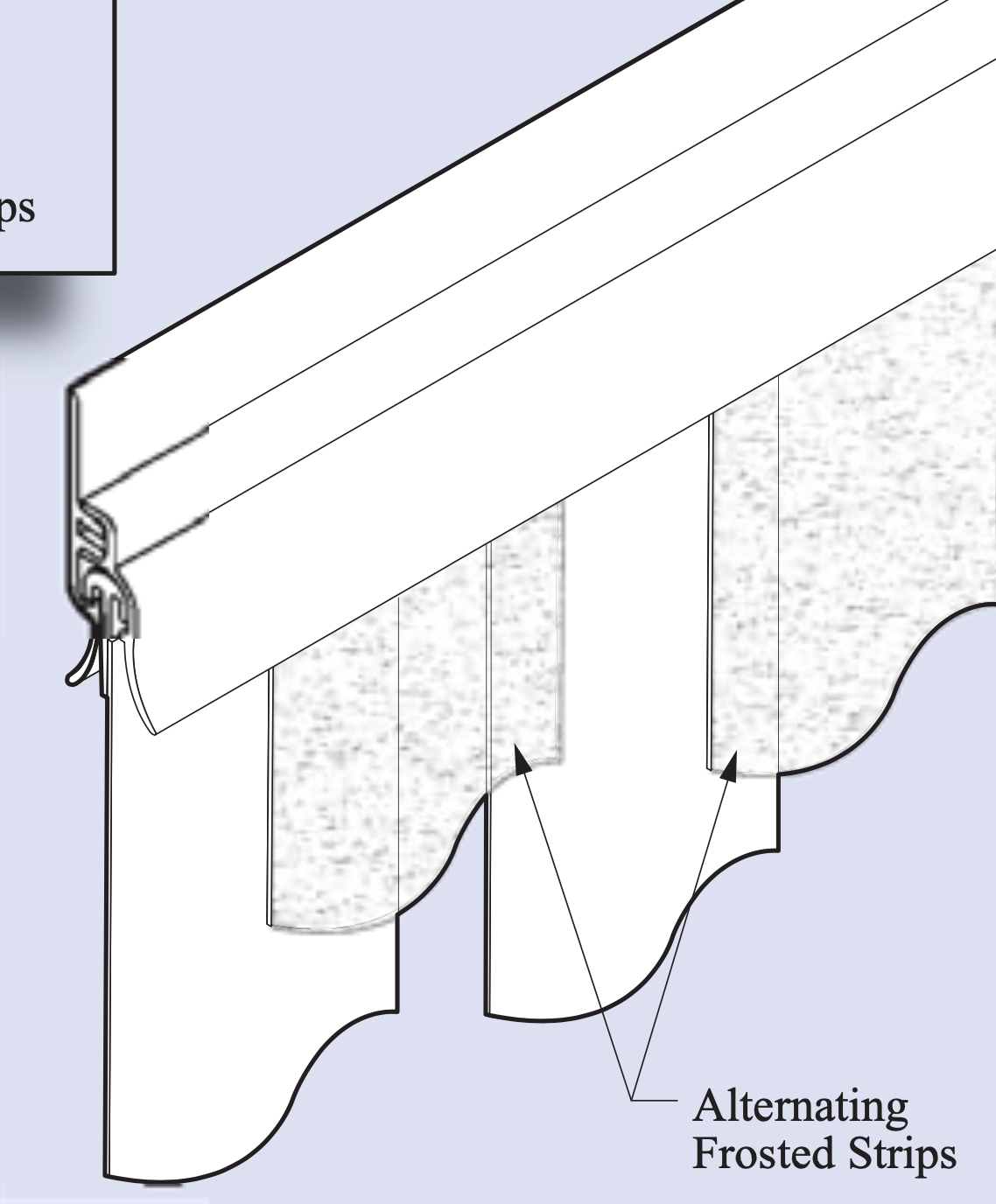

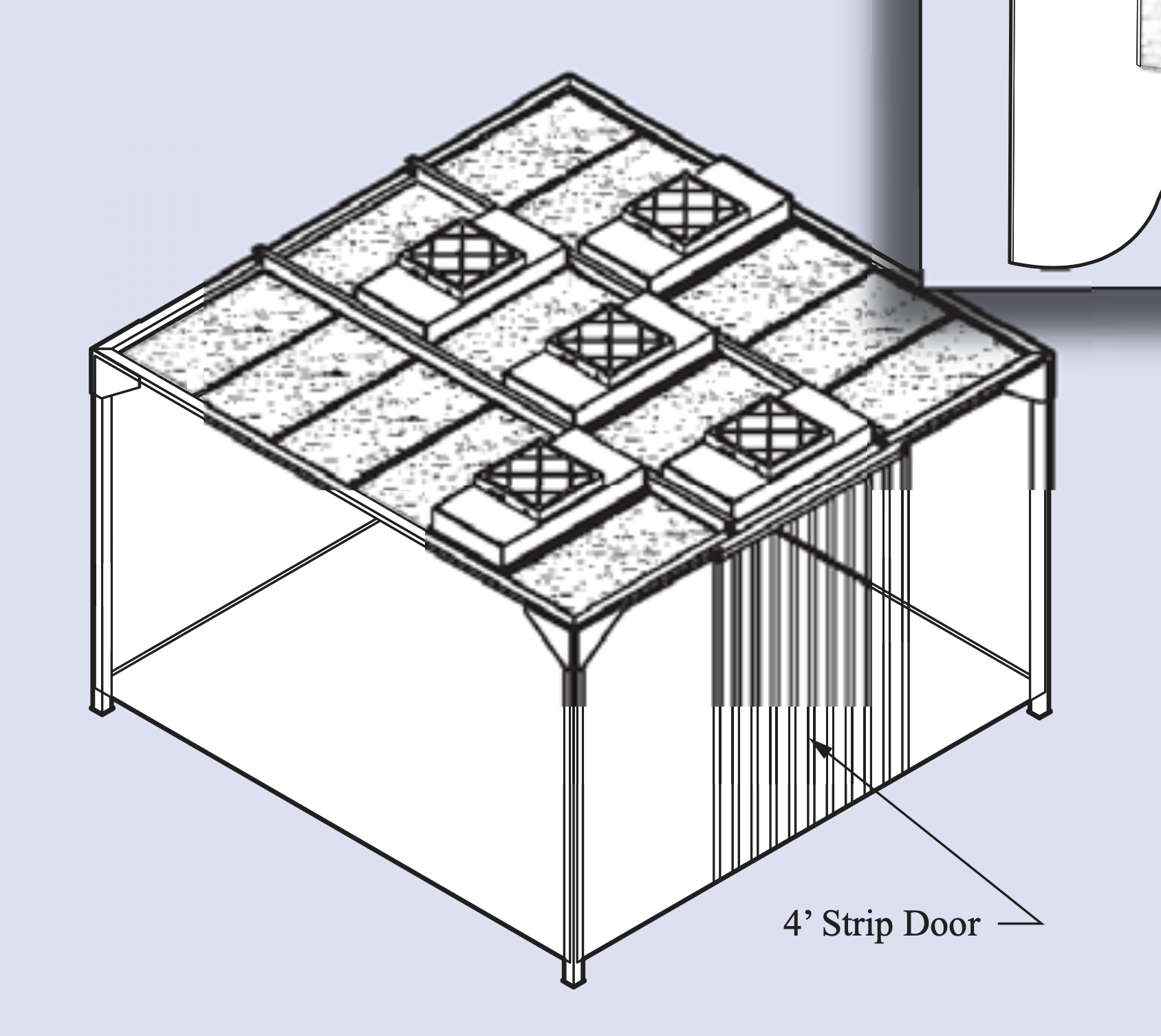

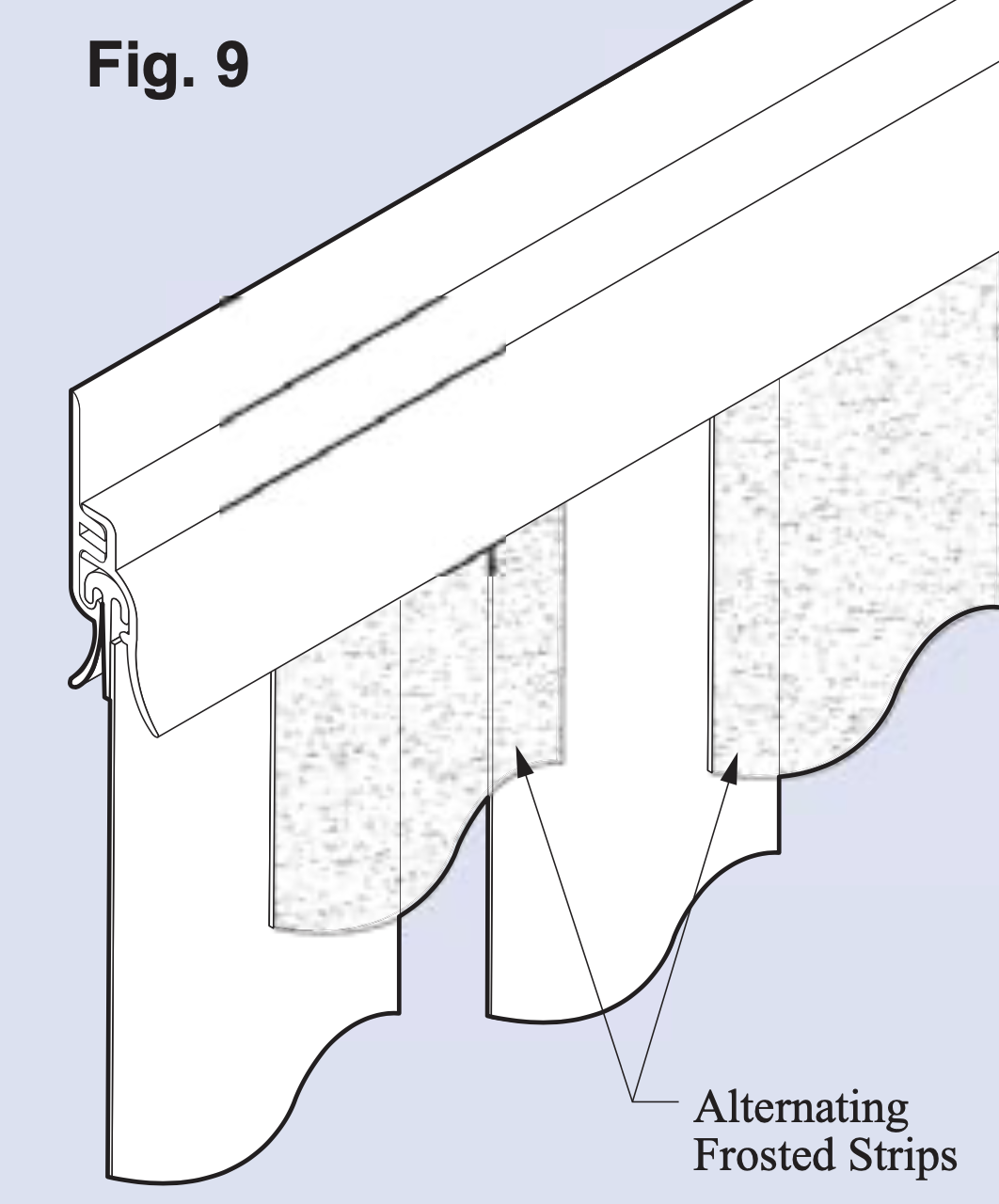

Standard Strip Door and Options

Our standard 4’ strip door consists of 8″ 80 mil clear vinyl strips overlapped 2″. Individual strips are factory installed on an aluminum mounting track. The strip door is attached to the cleanroom frame on-site during assembly. (Fig. 3, 4 & 5)

Optional strip doors with alternating frosted strips reduces friction between the strips and extends the life of the door. (Fig. 5)

Materials and procedures for cleaning your cleanroom, including general maintenance schedules, should be strictly followed as governed by your company policies.

Use Stryk-It Cleanroom and Laboratory cleaner diluted with DI or clean water. Dilution rates vary by usage.

Wash and dry with separate white cloths.

DO NOT use an abrasive or any type of cleaner containing alcohol or ammonia.

Specific to acrylic, the use of any cleaner or solution containing alcohol or ammonia will cause severe degrada- tion including cracking or “crazing”, and will void the warranty on the component and/or structure of which it is a part.

Ideal For Acrylic and Glass Windows, Softwall Curtain Panels and Door Strips Safe, Non-Toxic, Biodegradable

STRYK-IT Cleaner is a strong anionic, nonionic detergent formula coupled with alkalinity that creates water-soluble compounds form insoluble products making it a very effective cleaner in most industries today. Suitable for using in a cleanroom or laboratory on walls, floors, windows and equipment. Excellent for production parts washing. Economical to use in low foaming type of parts washing equipment and dip tanks.

Application

Characteristics

Directions

STRYK-IT to DI Dilution Ratios

Handling

STRYK-IT Cleaner and its dilutions are alkaline materi- als. Proper safety precautions should be exercised in the handling and the usage of this product. Thoroughly familiarize the personnel with the M.S.D.S. and safety precautions shown on the container label. (M.S.D.S. are available upon request.)

Mfg. code

Model or Description

19006

STRYK-IT 1 gallon (4 per carton)

19007

STRYK-IT 5 gallon pail

19008

STRYK-IT 55 gallon drum

19009

STRYK-IT Starter Kit (Includes 1 gallon Stryk-It, 1 gallon DI Water, 1 Spray Bottle, 1 Lint Free Wiper)

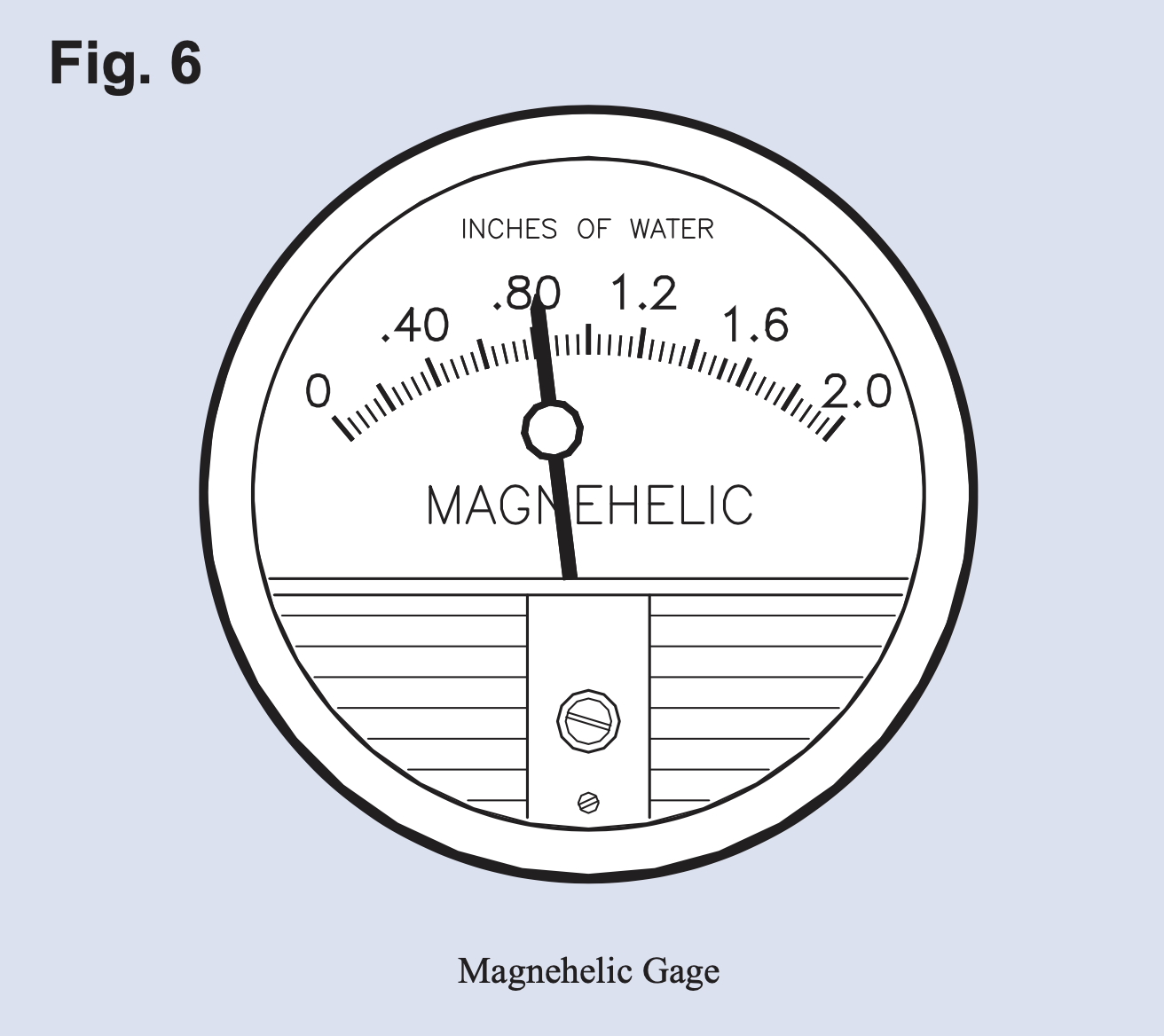

Magnehelic Gages

Monitoring the static pressure within the room can be accomplished by adding a Magnehelic Gage. (Fig. 6)

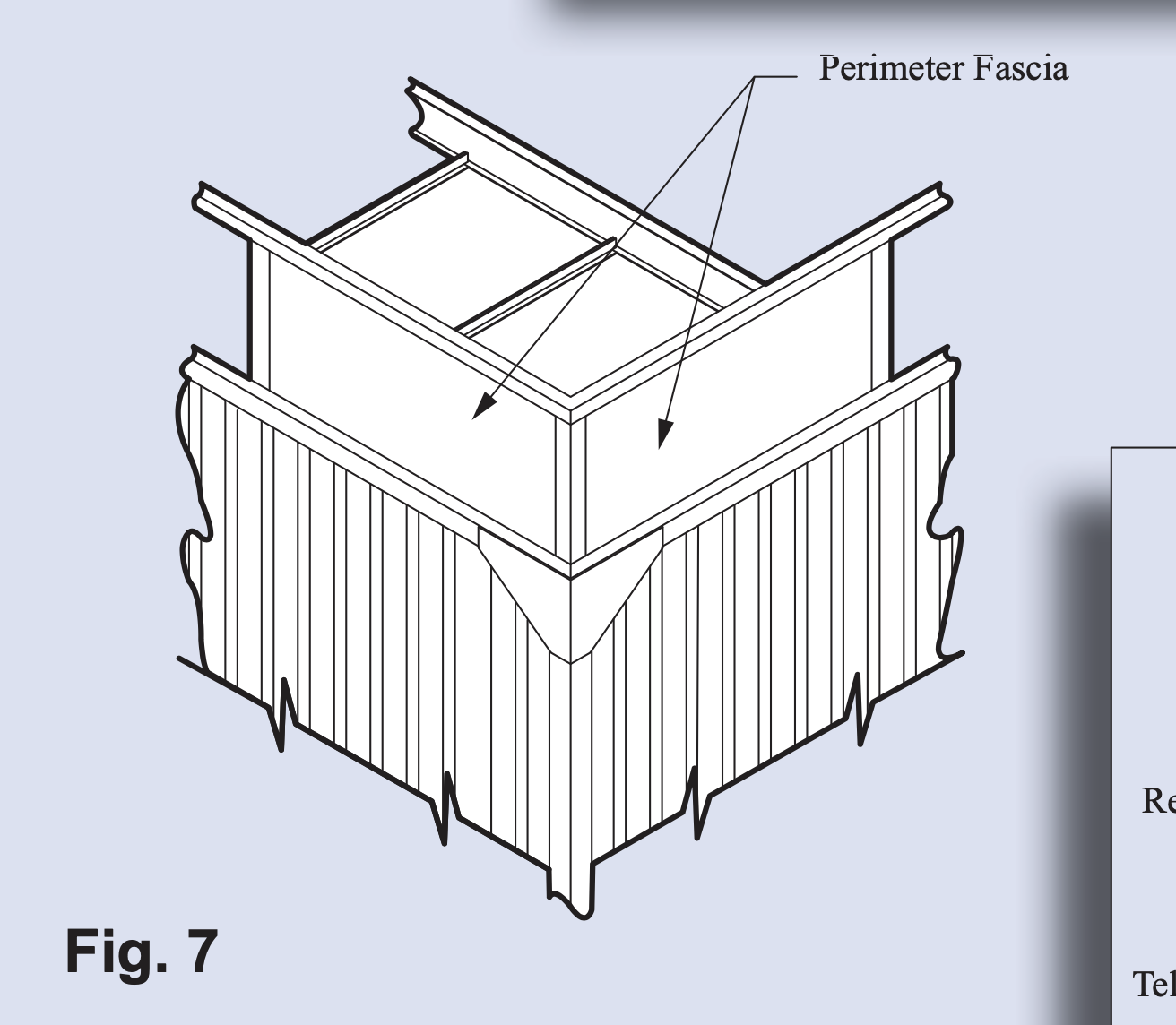

Perimeter Facia

An attractive white painted sheet metal perimeter facia (Fig. 7) prevents viewing the ceiling components from outside the room.

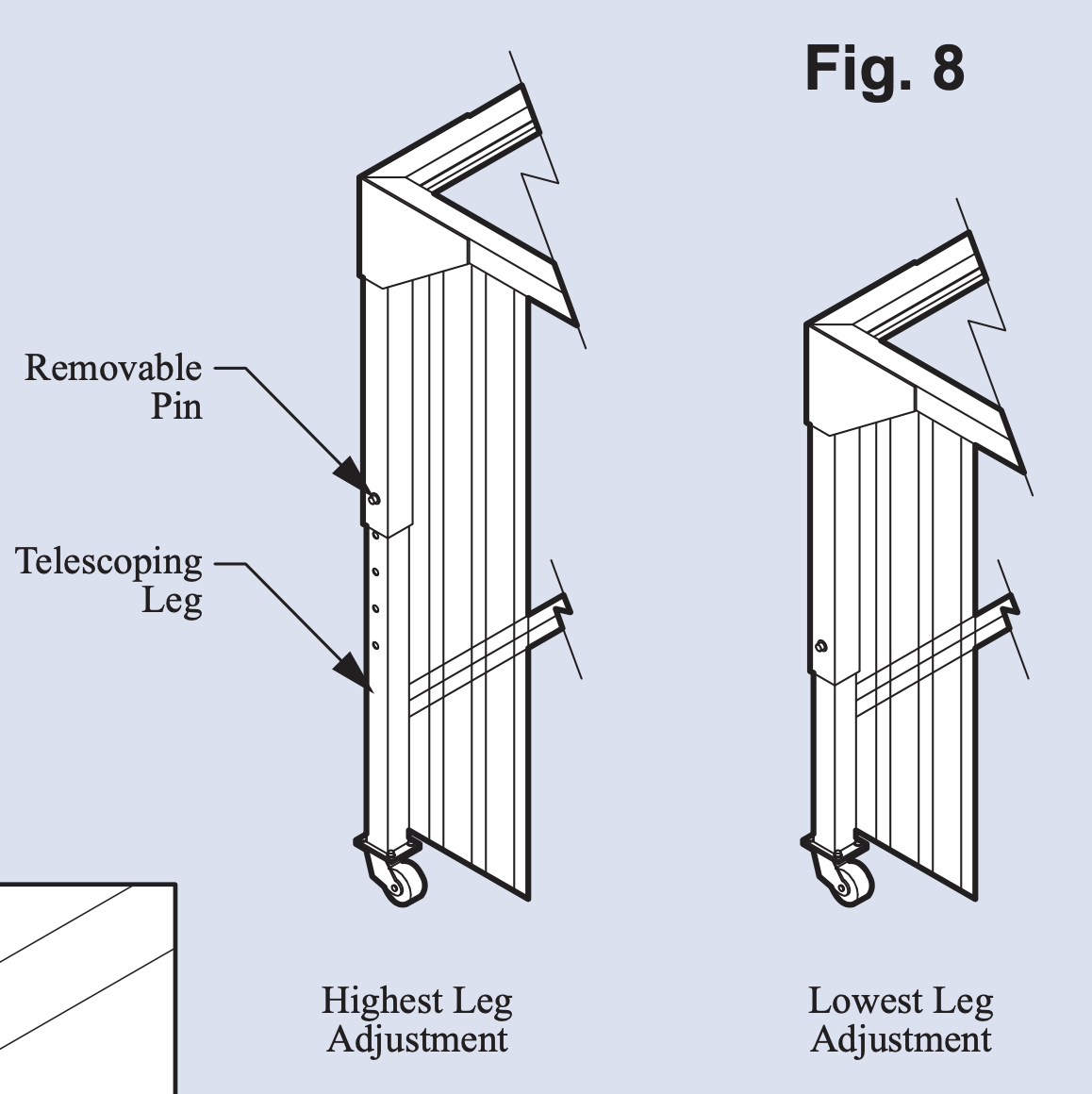

Telescoping Legs

Legs are adjusted by removing the pin, sliding the leg to another desired height, and replacing the pin. (Fig. 8) This feature is useful when the cleanroom must be moved through a doorway to another area.

More Options

Consult with your area representative or the CRI factory for your unique requirements.

Terms and conditions

©2026 Clean Rooms International, Inc